Cut Resistant PPE In The Glass Industry

We all know cut resistant PPE has been around in the glass industry for quite some time now. Especially those who manually handle glass have long been issued with such type of protective workwear / ppe in order to reduce the risk of injury.

As highlighted in the International Labour Organization Encyclopaedia of Occupational Health and Safety, the main risks for professionals working in the glass manufacturing sector are cuts, lacerations and soft tissues puncture wounds. All of which are most commonly result of coming in contact with sharp glass, broken glass and even cutting tools.

The above organisation also addresses similar risks for glaziers:

“…for glaziers, injuries, especially severe cuts to hands and feet… caused by glass sheets and their sharp edges during cutting, moving, setting, and other handling operations. Cuts and stabs caused by working tools, such as chisels, glass cutters, knives, etc.”

Why Cut Resistant PPE Is Needed

Based on records from the US Department of Labour...

"...manufacturers of glass products have a total “recordable” incidence rate of nonfatal occupational injuries and illnesses of 13.2 cases per 100 full-time workers per year. This incidence rate is higher than corresponding rates for all manufacturing (12.2) and all private industry (8.4). About 51% of the “recordable injury” cases in the glass product manufacturing sector do not result in lost workdays (time away from work)."

These figures alone clearly warrant to investigate all available forms of cut protection further.

But we are also aware that glass manufacturers have a total lost workday incidence rate of 6.5 cases per 100 workers per year. About 93% of the lost workday cases in the glass manufacturing sector results from injuries rather than occupational illnesses, according to the Switzerland headquartered International Labour Organization.

The U.S. Bureau of Labor Statistics reported:

"...approximately 900,000 workplace injuries that resulted in days away from work in 2012. Both glazing contractors and glass manufacturers reported higher than average incidences of injury or illness during the year. 133.7 for glazing contractors and 118.9 for glass manufacturers."

Cut resistant PPE starts to make real operational sense in the glass production and processing industry.

Reports published by the Queensland (Australia) Government suggest that in Australia...

"...since 2012, there have been 126 glass smashing incidents, 13 involving stacks or racks of glass paneling. It is further reported that there have been 157 accepted workers’ compensation claims for injuries received as a result of falling glass. This means on average; 31 claims are accepted each year for workers injured by falling glass."

The UK's Health and Safety Executive (HSE) on Cut Protection

In the United Kingdom, the HSE (Health and Safety Executive) offers guidance on safety in the handling of flat glass (see report):

“The handling of flat glass involves the risk of serious personal injury. HSE experience has shown that although the risk is higher in factories where flat glass is manufactured. Serious accidents continue to happen in premises where glass is subsequently handled and processed”.

According to HSE, accidents can occur during vacuum handling: “large sheets of glass are routinely handled using vacuum lifting frames, these can involve the risk of being struck by falling glass”, in the warehouse during loading the glass sheets onto the vehicles, when the load can fall sideways, with the same risk applying to unloading. Racking is also very important, as bowing and venting will occur if the angle of lean in the sheet glass racks is too great from the vertical, but sheets will be unstable and be pulled over by draughts if the angle is too small.

The HSE concludes:

“…appropriate protective clothing should be worn when glass is handled manually”.

Fundamental of Risk Assessments

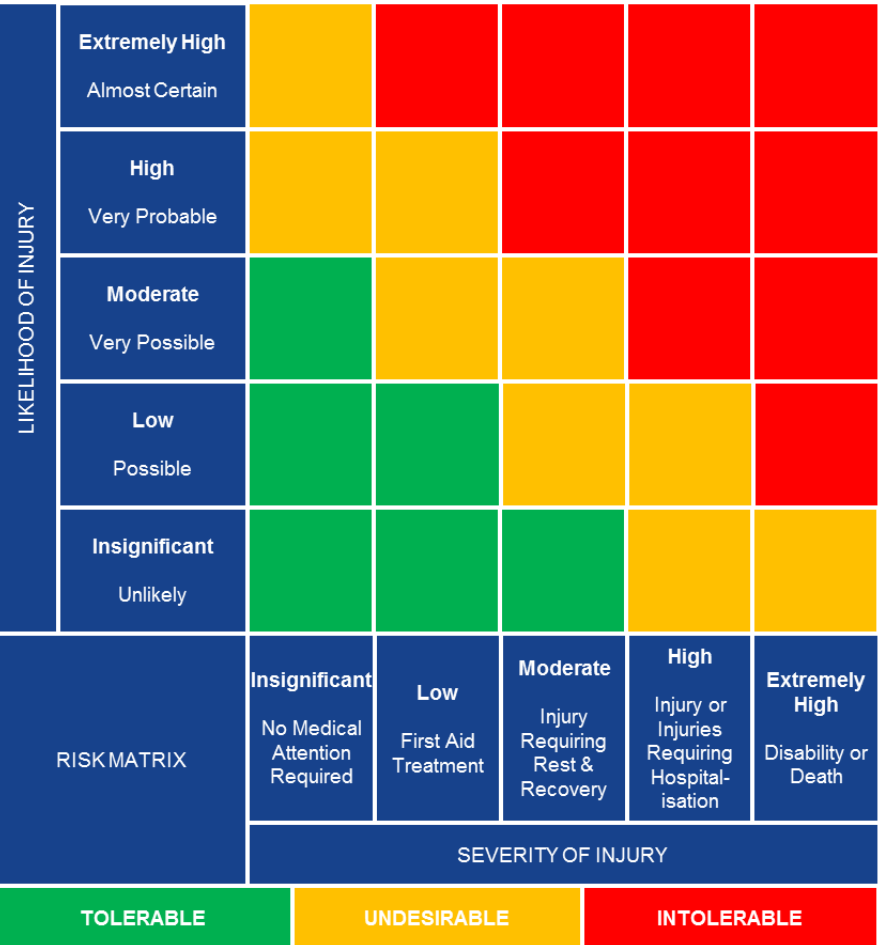

When carrying out a risk assessment, hazards and risks must be the key considerations:

- HAZARD: Anything that may cause harm

- RISK: The chance, high or low, that somebody could be harmed by these and other hazards, together with an indication of how serious the harm could be.

A risk assessment doesn't need to become another ‘War & Peace’ novel… a massive document in a huge ring binder no none will ever end up reading. It can indeed be a simple document, which states that a risk has been identified and that all consideration was given to establish on how to mitigate that risk.

Consideration should be given to the likelihood of occurrence, the likelihood of harm and the consequence (severity of injury). In general, risks should be reduced to a level that is as low as reasonably practical.

The following is a common format for illustrative purposes of a risk matrix follows. It is a simple yet highly effective to classifying risk, and would be expected to be used conservatively when assessing likelihood and severity.

We believe that CutPRO® Cut Resistant Clothing is very much your ultimate choice when it comes to durable and 'operationally sound' PPE. PPE which will help you to mitigate the risk identified in your risk assessment!

Our cut resistant PPE is made from 100% Cut-Tex® PRO – the world’s most advanced cut resistant fabric. It is the result of extended research and valued input from senior safety professionals of leading flat glass and sheet metal companies around the world. It offers ANSI/ISEA 2016 Blade Cut Resistance Level A5. Besides exceptional levels of cut protection, it also offers the highest levels of puncture and tear (EN 388:2016).

Our garments can effectively help you replace three items:

- Cut Resistant PPE – its cut resistant capabilities will eliminate the need for additional garments/layers

- Workwear Uniform - the garments are designed to look like a standard workwear uniform, with options for colours and company logos

- High Visibility Garments – some facilities require the staff to wear extra layers with hi-visibility, and to replace this need, on each of our garment we can use high visibility tape/high visibility colours.

Please view our product range online and email us for further information: info@cut-pro.com

Robert Kaiser, CEO

PPSS Group / CutPRO®

About the Author

Founder and company CEO Robert Kaiser is renowned expert in the prevention of workplace violence related injuries, and also author of "NEVER A VICTIM - The Definitive Guide to Women's Safety".