Cut resistant clothing or workwear is often rated by cut levels actually associated to the testing of ‘protective gloves’. Such products are commonly labelled as something like “cut level 1” or “cut level 5” gloves, shirts, jackets or trousers. Here we will explain better what it means and what cut level is the right one for you.

A cut level is determined by cut resistance standards

There are several standards used for determining how difficult it is to cut through a glove, garment, or fabric.

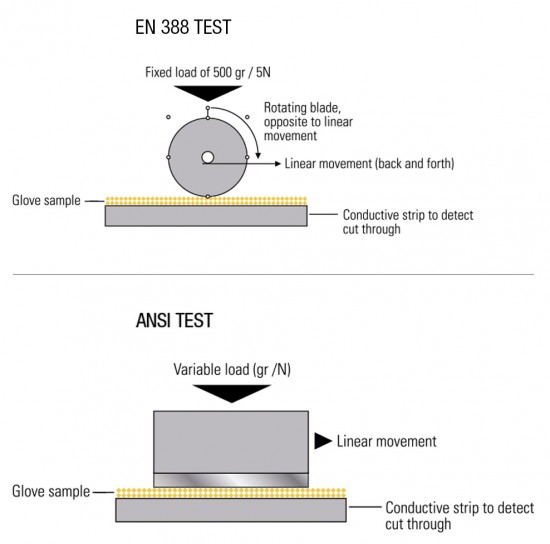

In Europe, we used to have the EN 388:2003 standard, resulting in anything between Cut Level 1 and Cut Level 5. This cut-test method, called the Coup test, uses a constant weight on a rotating circular blade that is moved back and forth across a sample by the test machine. However, this test is no longer seen as ‘ideal’ to measure the cut resistance of gloves, garments or fabrics made from high performance cut resistant fabric, such as Cut-Tex® PRO. Those have been 'engineered' using a specific fibre composition (including glass fibres, stainless steel, or a mixture of technical fibres) that will ultimately dull the test blade, and hence can lead to an incorrect and artificially high cut level.

The revised version is capable to test those 'high performance cut resistant fabrics' and products. The EN 388:2016 is today’s mandatory performance standard in Europe. It is using the ISO 13997 test protocol and the TDM-100 cut test machine, resulting in performance levels ranging from Cut Level A to Cut Level F. Cut Level E and F are widely seen as ‘high cut resistance levels’

Designed to now also test high performance cut resistant fabrics or clothing, the TDM-100 cut test machine (Tomodynamometer) delivers undisputable results. This test involves the interpretation of data obtained from employing and increasing the level of force/weight of the strong rectangular test blade (which looks a little like an oversized razor blade) to cut through the object and then recording the distance the blade will have travelled before ultimately cutting through it.

In America, the most common referred to standard is the ANSI/ISEA 105-2016 which is based on values obtained using the ASTM F1790-05 method, using the very same TDM-100 cut test machine. Please note that the previous version, the ASTM F1790-04 was using the Coup test (as per EN 388 standard), but for the very same reason changed the test apparatus to the TDM-100 cut test machine to establish greater accuracy and a more reliable cut level.

The ANSI/ISEA 105-2016 standard and test result in performance levels reaching from A1 to A9.

There is of course much more that can be said about cut protection levels, tests and standards, but in my humble opinion it often will lead to further confusion, rather than clarification.

The Right Cut Level For Cut Resistant Workwear

So, what cut level do you need when, for example, considering cut resistant workwear in the flat glass or sheet metal industry?

Most professionals will agree, ANSI 105-2016 Cut Level A5, ISO 13997/EN388:2016 Cut Level E are both ideal for individuals who either come in contact with, or who are required to manually handle sharp blades or sheet metal, or those working in the flat glass or float glass production and processing industry. Such cut level will offer outstanding and sufficient protection and yet can be user-friendly and comfortable.

We at CutPRO® are true believer of ‘the best is not good enough’, stating our relentless desire to improve what we do. Our cut resistant workwear offers the above ‘benchmark’ protection levels, because we simply believe it is better to be on the safe side, as long as protective garments remain lightweight, thin and breathable.

However, please note cut resistance tests and levels are just one element of what needs to be considered. There are two additional protection levels you should investigate before purchasing cut resistant garments:

Puncture Resistance

Often punctures are misreported as cuts. A sharp edge, corner or other overhanging sharp hazard can penetrate the glove or garment and cut your skin. With many gloves or garments being made from a knitted fabric, and depending on the density of the knit, the gauge of the fabric (the measure of the number of knitting needles per inch) and the thickness of the fibres, such protective garment/fabric is leaving ‘tiny windows’ (knitting loops) potentially still allowing a more pointed sharp object to cause a puncture or cut injury.

The EN 388:2016 test standard is resulting in level 1 to level 4 of puncture resistance. All garments made by CutPRO® offer the highest puncture resistance level 4.

Tear Resistance

Subject to the precise job responsibilities and work environment, and the usual ‘wear and tear’, every garment can ultimately develop tiny, often unnoticeable cuts. The time in takes for those tiny and unnoticeable cuts to turn into larger cuts and holes, exposing the wearer to much greater risks of cut injuries and laceration, is primarily determined by the garment’s tear resistance. A protective garment can offer anything between EN 388:2016 level 1 to level 4 of tear resistance. All garments made by CutPRO® offer the highest tear resistance level 4.

If you have any additional questions or need further assistance, please don't hesitate to reach out to us. You can contact us by phone at 0845 5193953 or via email at info@cut-pro.com.

If you want to view our full range of cut resistant clothing, please download our latest 2023 catalogue.

About the Author

The company’s Founder and CEO Robert Kaiser is an expert in women’s personal safety and author of the book NEVER A VICTIM – The Definitive Guide to Women’s Safety, the result of over three decades of dedicated research and experience in understanding both physical and sexual violence against women. This indispensable resource will empower all female readers with the knowledge and confidence to trust in their instincts and innate ability to protect themselves. With 514 pages and over 111,000 words, this is a truly comprehensive book on this important subject, and arguably a respectable answer to the question: What is the best book on women’s safety? Robert is also author of several relevant articles such as Best Essential Travel Safety Tips for Women Travelling Solo