It is truly astonishing to see how far manufacturers and suppliers of cut resistant clothing are willing to go in order to secure a larger portion of the market share.

Driven by a hunger for profits and blind sense of competition, and willing to neglect even the clearest legal requirements, companies across Europe are prepared to risk the safety of workers in the glass production industry.

CE Marking

Just very recently I came across yet another firm arguing that CE marking is really not all that important. It was their Managing Director who said” “We sell our clothing as workwear. We don’t need CE marking if we sell it as workwear, and our customers are ok with that.”

Just very recently I came across yet another firm arguing that CE marking is really not all that important. It was their Managing Director who said” “We sell our clothing as workwear. We don’t need CE marking if we sell it as workwear, and our customers are ok with that.”

My heart literally stopped beating for a brief moment. Is this a person saying that, who simply lacks knowledge? Someone who is frankly unaware of precise European laws, rules and regulations? Or was I listening to yet another businessman willing to do wrong in order to impress shareholders?

As a supplier of Personal Protective Equipment (PPE) it is legal responsibility to ensure that all products sold are compliant with European law and legislation. This is to guarantee the health, safety and well-being of those purchasing and wearing those products.

The supporting law within Europe is ‘Regulation (EU) 2016/425’ which clearly states that all PPE must be CE certified. There is no question about it, not to comply with this law is a direct breach of not only European law but the laws of that member state.

The following is a just an abbreviated version, highlighting the key points, which are unquestionable:

- All clothing to be worn or held by any end user to offer any type of protection is PPE and as such MUST be CE certified for sale in the European Union.

- If your customer is using the clothing for protection and/or to improve the health and safety of the wearer at a workplace then they should be using appropriately CE market products (if using or selling within the EU)

- You are not allowed to sell anything within the EU that could be defined as PPE without appropriate CE Marking

- You must bring all issues of non-compliance to the attention of the manufacturer

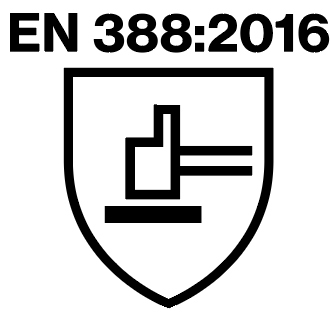

Change of Performance Standards

Most Health & Safety professionals charged with the safety of flat glass and sheet metal workers will be aware of the European Standard EN 388:2003 “Protective gloves against mechanical risks”. This is the standard most cut resistant clothing manufactures and suppliers will use in order to highlight the performance levels of their garments.

Historically the EN 388:2003 was the standard to go by, simply because ‘protective gloves’ have been around for a very very long time, and it helped health and safety professionals as well as those charged with making corporate purchases to make an informative decision, comparing performances and prices.

However, many cut resistant clothing manufacturers seem to have ‘simply forgotten’ that this standard has already been superseded, as it in many cases highlights a weakness in their cut resistant fabric. This new, updated version, the EN 388:2016, is much more stringent and offers the end consumer a much more realists ‘real life’ result.

The main change within the cut resistant testing under EN 388:2016 is that the gloves/garments will now be tested by a TDM-100 cut test machine, using a rectangular blade. In 2003, they were tested to a circular blade only. Gloves/garments will now receive between a Level A and a Level F, with Level F being the highest that a glove can achieve. The highest levels of cut resistance under the new standard (Level C to Level F) are more comprehensive and accurate.

Please read our CEO's very informative article, titled: "The Right Cut Level: All You Need To Know".

The abrasion testing is now carried out using different test paper. As a result, gloves or garments may receive a lower score under EN 388:2016 to the score originally awarded under EN 388:2003.

Also, even if there is no change as such in the testing procedure of the puncture resistance, it is worth to state how relevant that part of the EN 388:2016 is. There is no guarantee that a garment made from a puncture resistant fabric will stop a sharp object, but there is no question about it, such garment has a much better chance of preventing or reducing an injury compared to a garment made form a fabric offering a low or no puncture resistance.

I strongly recommend to everyone involved in the production and processing of flat glass or sheet metal to request test reports highlighting the performances according to the EN 388:2016 version, as this will ultimately help you to further improve the safety of your workforce.

Secondly, I urge glass producers to request a copy of the CE marking certification from whoever you purchase your PPE from. Please do not jeopardise the health, safety and well-being of your workforce.

Any questions?

CONTACT US

Robert Kaiser, CEO

CutPRO®

About the Author

If you’ve enjoyed this article, you may be interested in learning more about the work we do at CutPRO®. Robert Kaiser, our company’s Founder & CEO, is a globally respected expert in combating and mitigating violence, as well as risk management. He is also a gender-based violence specialist and the author of NEVER A VICTIM – The Definitive Guide to Women’s Safety, written after three decades of research. His recent articles include The Best Personal Safety Tips for Women.